Explore the world of our state-of-the-art laser engraving and cutting solutions. Our advanced technology brings intricate designs to life. From ADA tactile signage to industrial lamacoid tags to industrial prototypes, discover the possibilities today.

Laser engraved stainless steel housing for Web Vision

Laser etched stainless steel dogtag

Laser etched industrial marking on 3mm solid brushed aluminum

Laser etching on sword blade

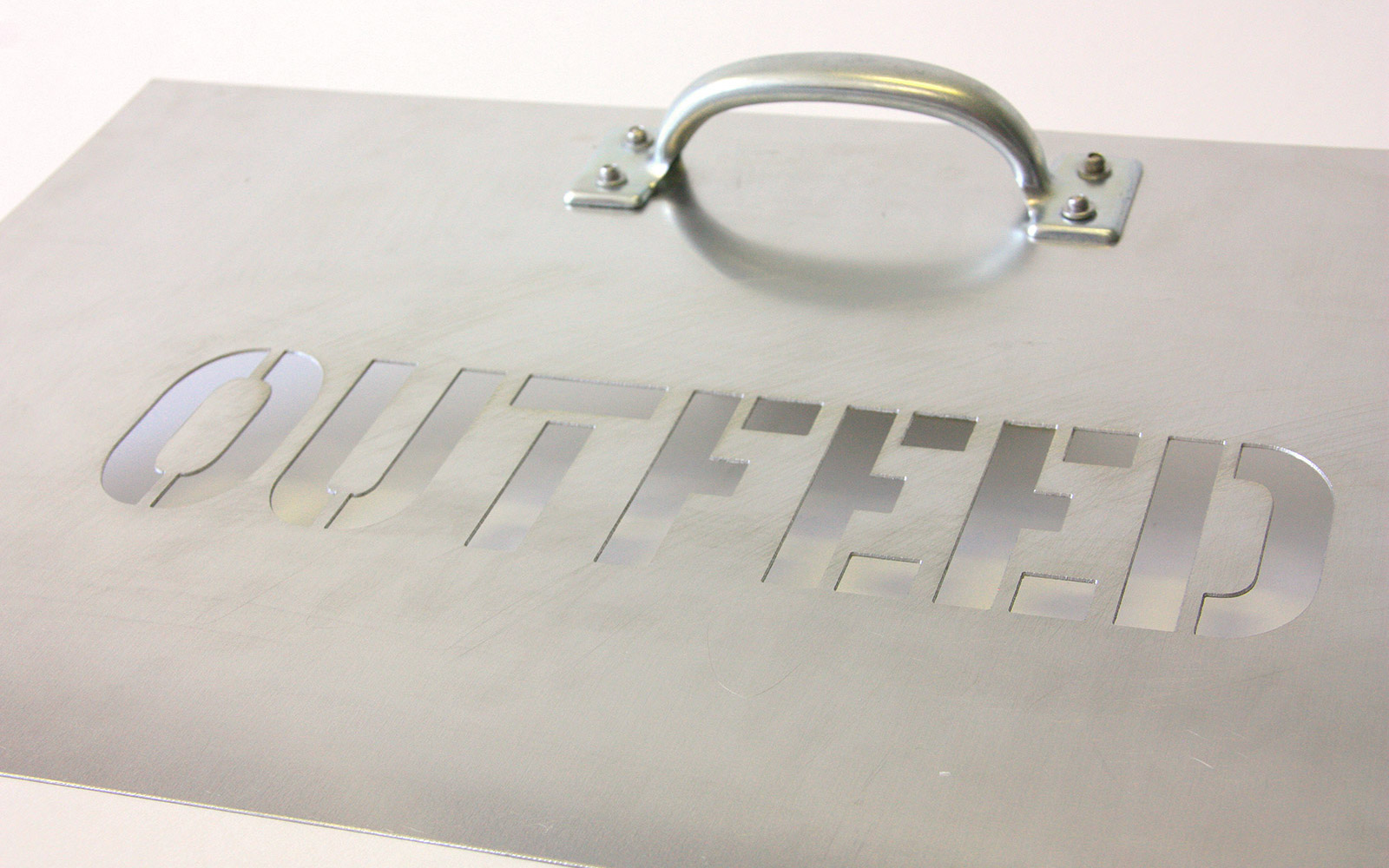

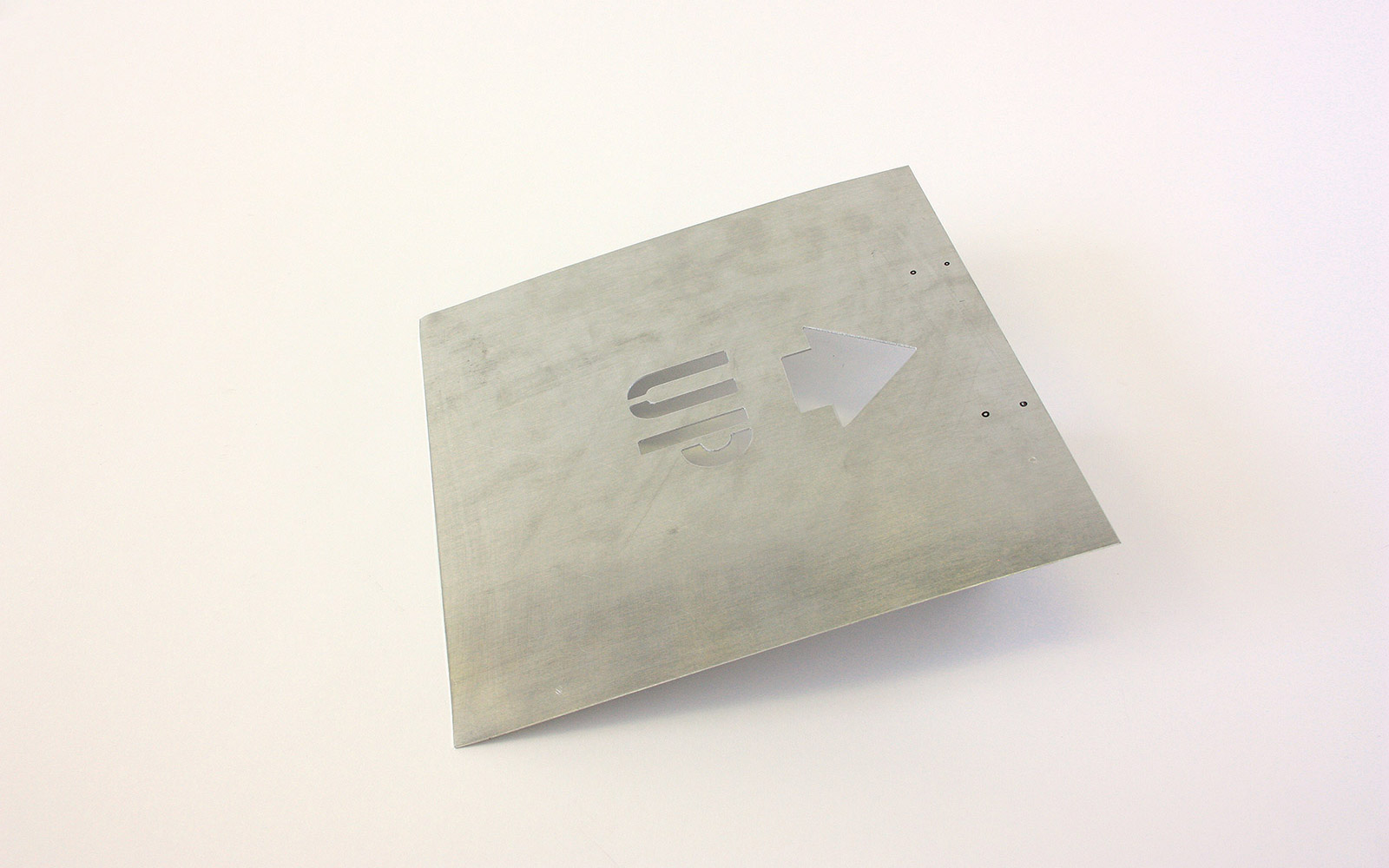

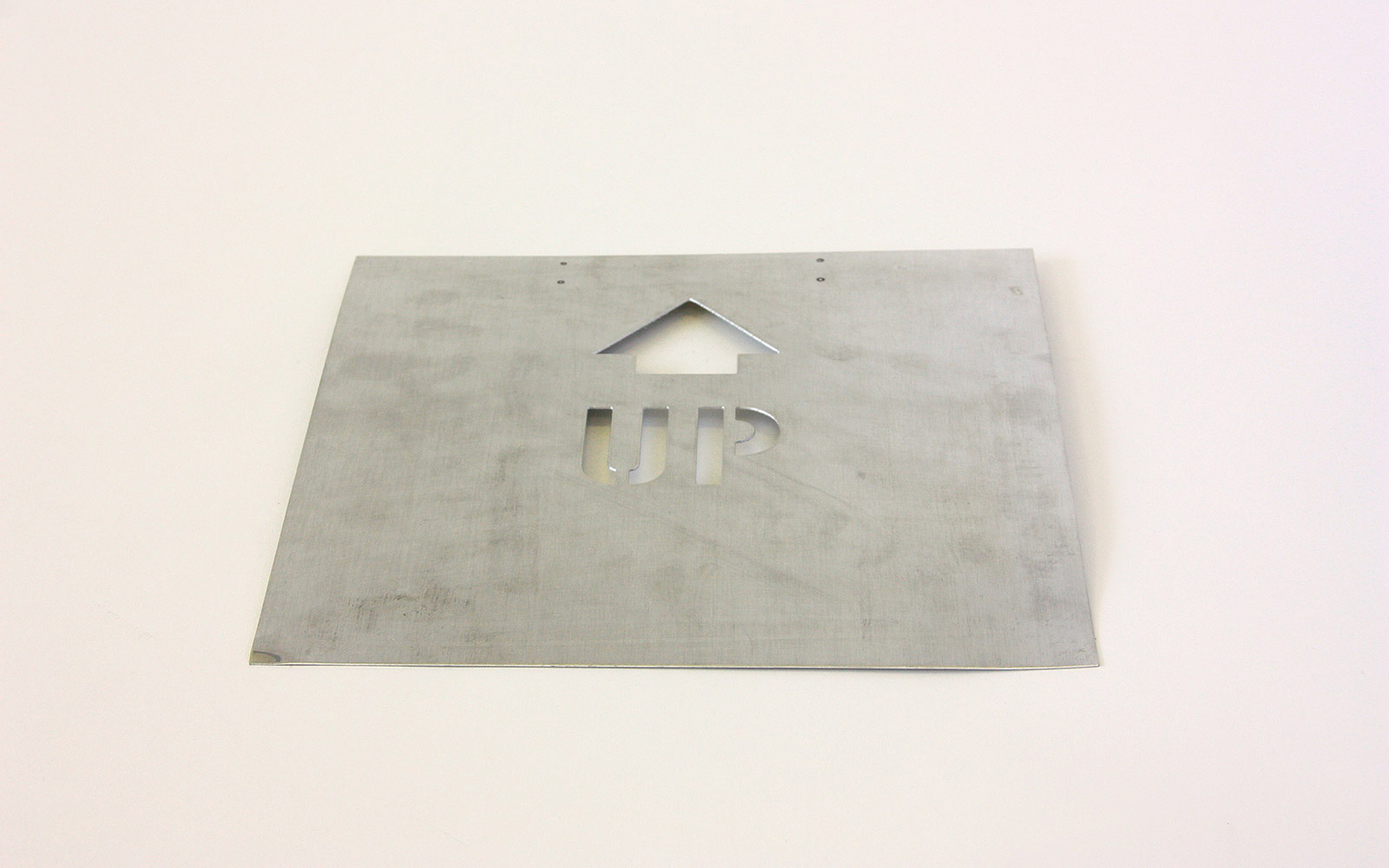

Custom Industrial marking plate cover sample

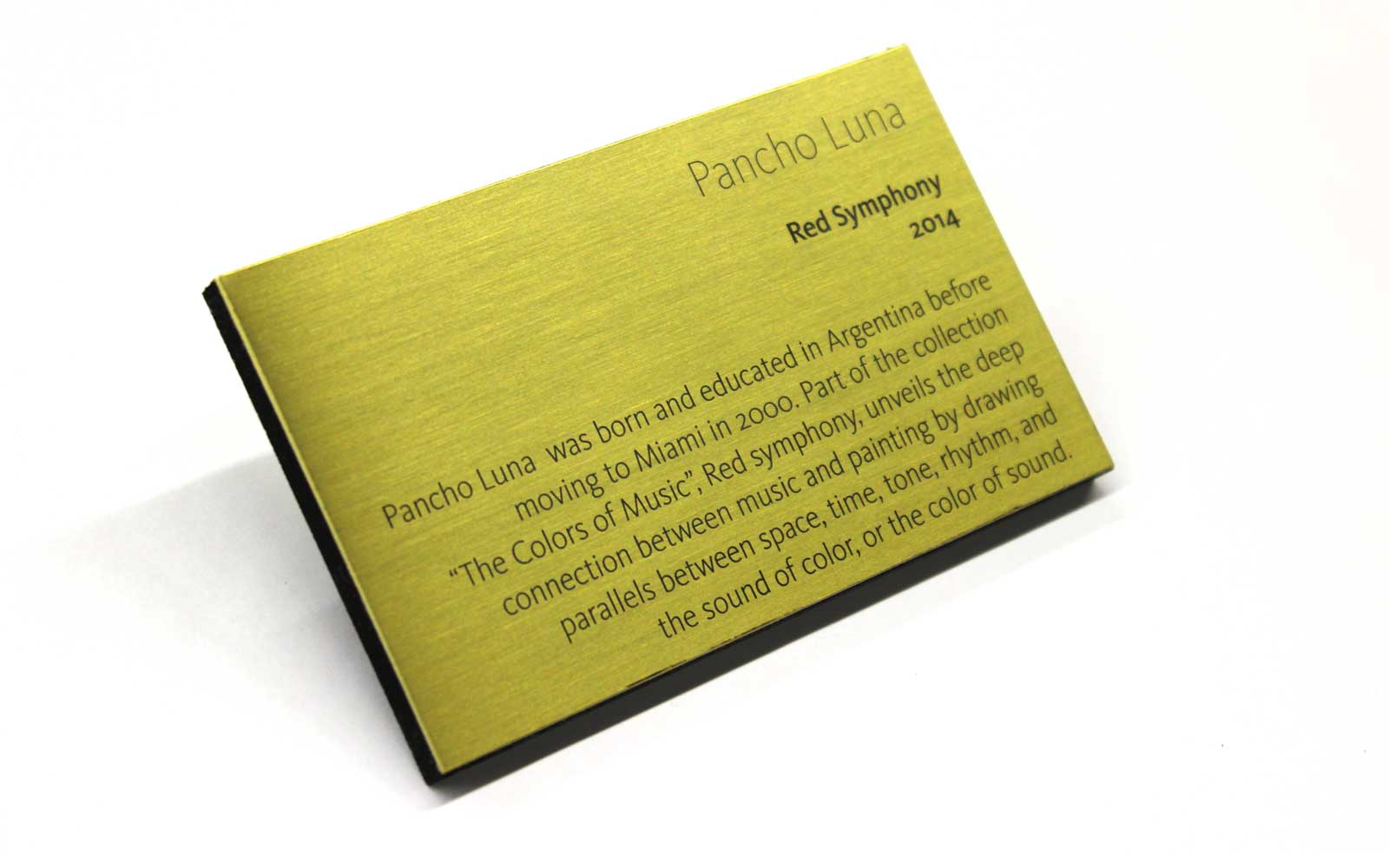

.025" brass plaque with burnished and blackened text on a 1/4" black sintra backer

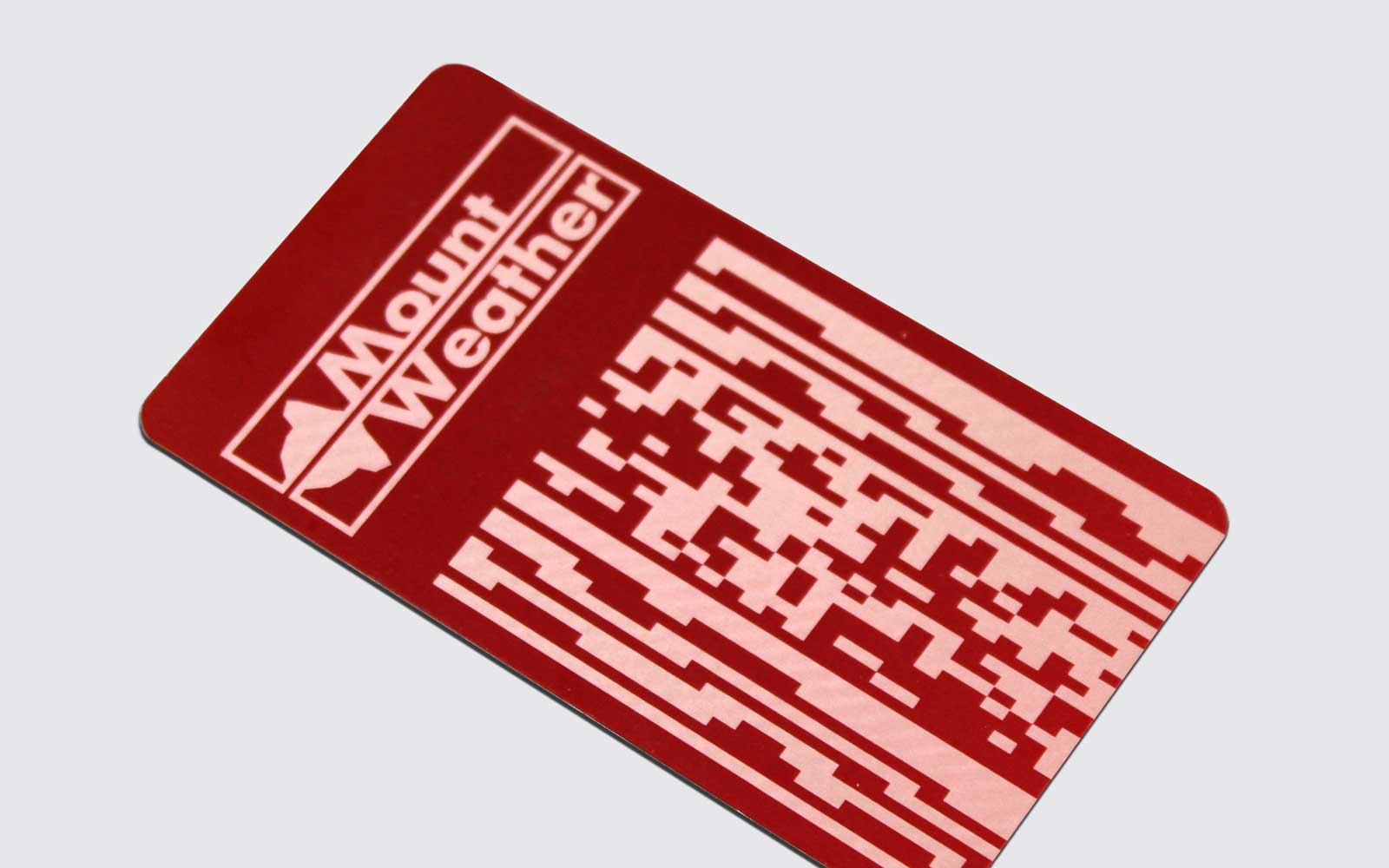

Red anodized aluminum access card with white laser etching

Red anodized aluminum access card with white laser etching

Diecut gold anodized alumamark picture frame with black laser etched graphics 12" x 14"

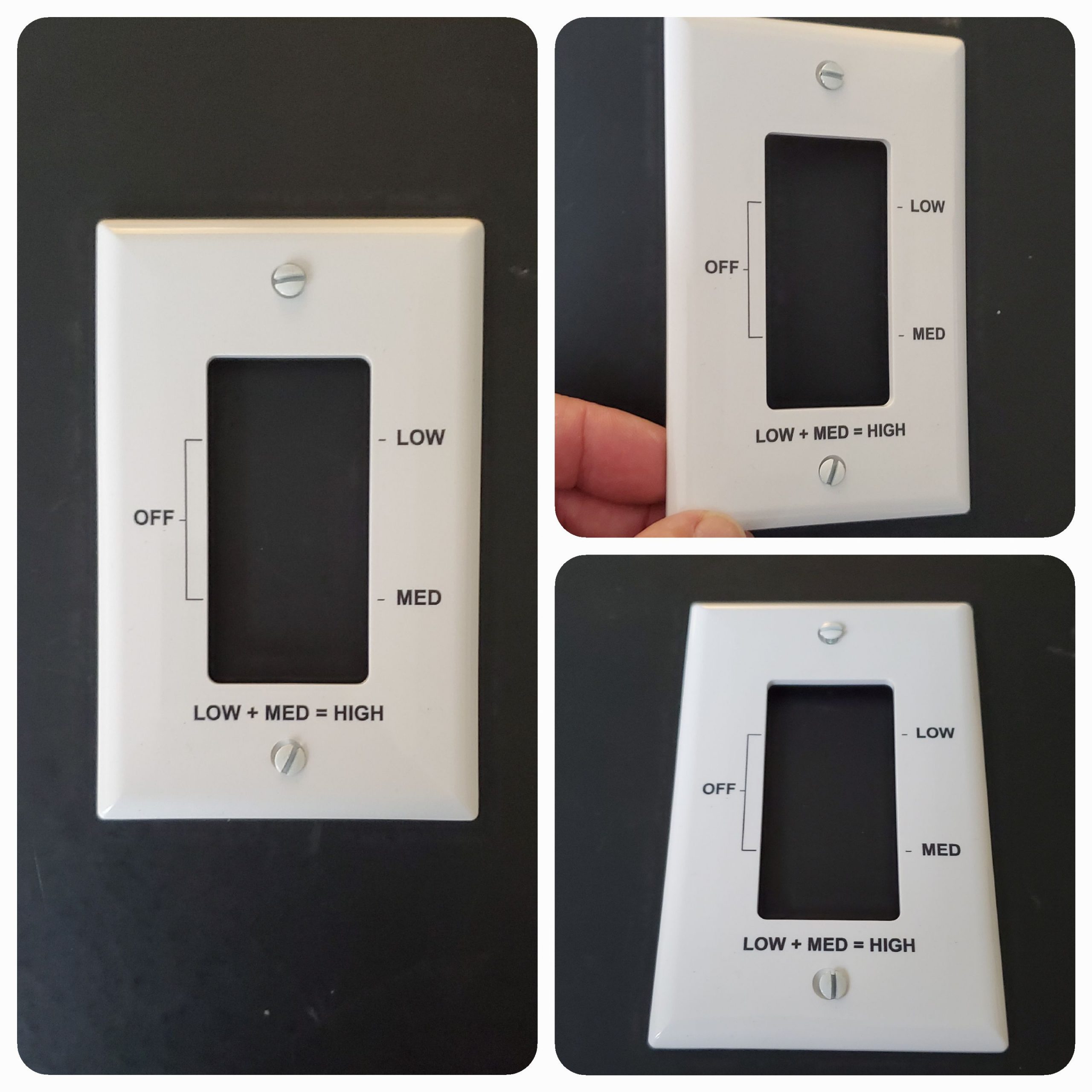

Laser engraved plastic warning directional sign

FAQs for Industrial Marking and Laser Etching

What is the difference between laser etching and laser engraving?

hile the terms laser engraved and laser etched are used interchangeable at times, they are different processes with different end results.

Laser etching is when we use our laser technology to alter the surface of the material and the laser beam “marks” the the copy and graphics on the surface without removing any material. Laser etching can change the colour of the area where the copy and graphics are “marked”. After laser etching the area is smooth and does not have a recess feel to the copy and graphics. Permel can laser etched items like acrylic, awards, glassware, stainless steel cable tags, Yeti Tumblers, and even wood products. Laser etching is creates a clean, crisp, easily to read copy and graphics and is idea for industrial markings applications like adding serial numbers to client supplied items and great promotional items like Yeti Laser Etched Tumblers.

Laser engraving is the process where we uses our laser technology to physically remove material and create a permanent marking when engraved copy and graphics. The laser engraving process makes the copy and graphics “recessed” into the surface if the material. You would be able to feel the recessed copy and graphics if you ran you fingers across the laser engraved area. Permel can laser engrave products like lamacoids, nametags, acrylic, some plastics, and some coated metal products to leave a clean, crisp, and permanent client copy.

In summary, laser engraving involves the removal of material to create a deep, permanent mark, while laser etching alters the surface without significant material removal, resulting in a shallower and often less tactile mark. The choice between engraving and etching depends on the specific application, material, and desired appearance of the marking.

Can you laser etch serial numbers on my industrial parts?

Yes, we can laser etch you serial numbers or copy/logos, directly on to your client supplied industrial parts. The most common parts are stainless steel and anodized aluminum, but contact us directly at info@permel.com to review your specific project.

What type of material can I laser etch?

We can laser etch materials like acrylic, lamacoids, stainless steel, anodized aluminum, glass and other client supplied items.

See other Permel products listed below

-

0

3D Dimensional Lettering Signs

Make a statement the moment visitors step into your space with our stunning 3D Dimensional Reception Signs. Crafted with precision and designed for impact, these business identity signs are a powerful representation of your brand.

-

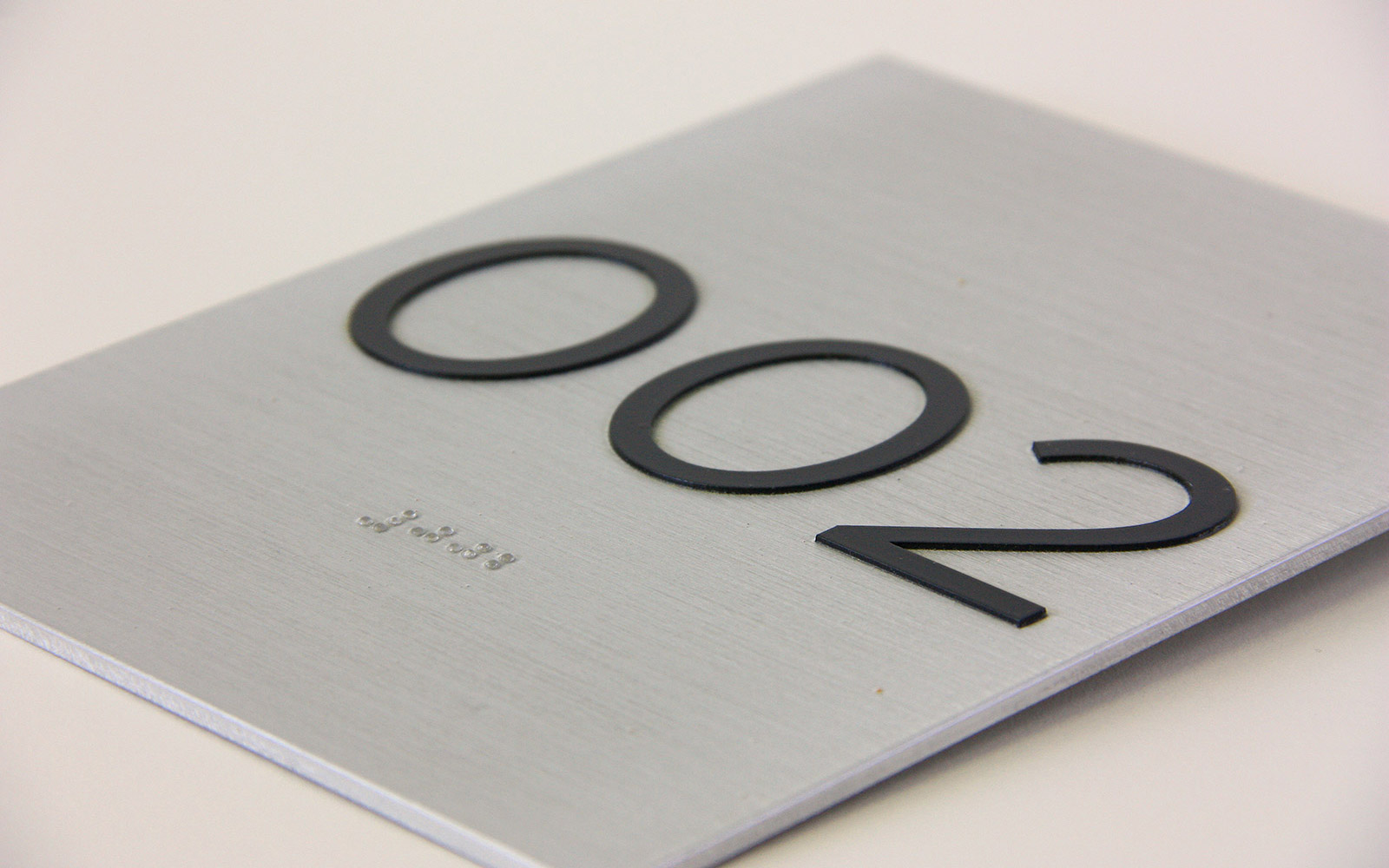

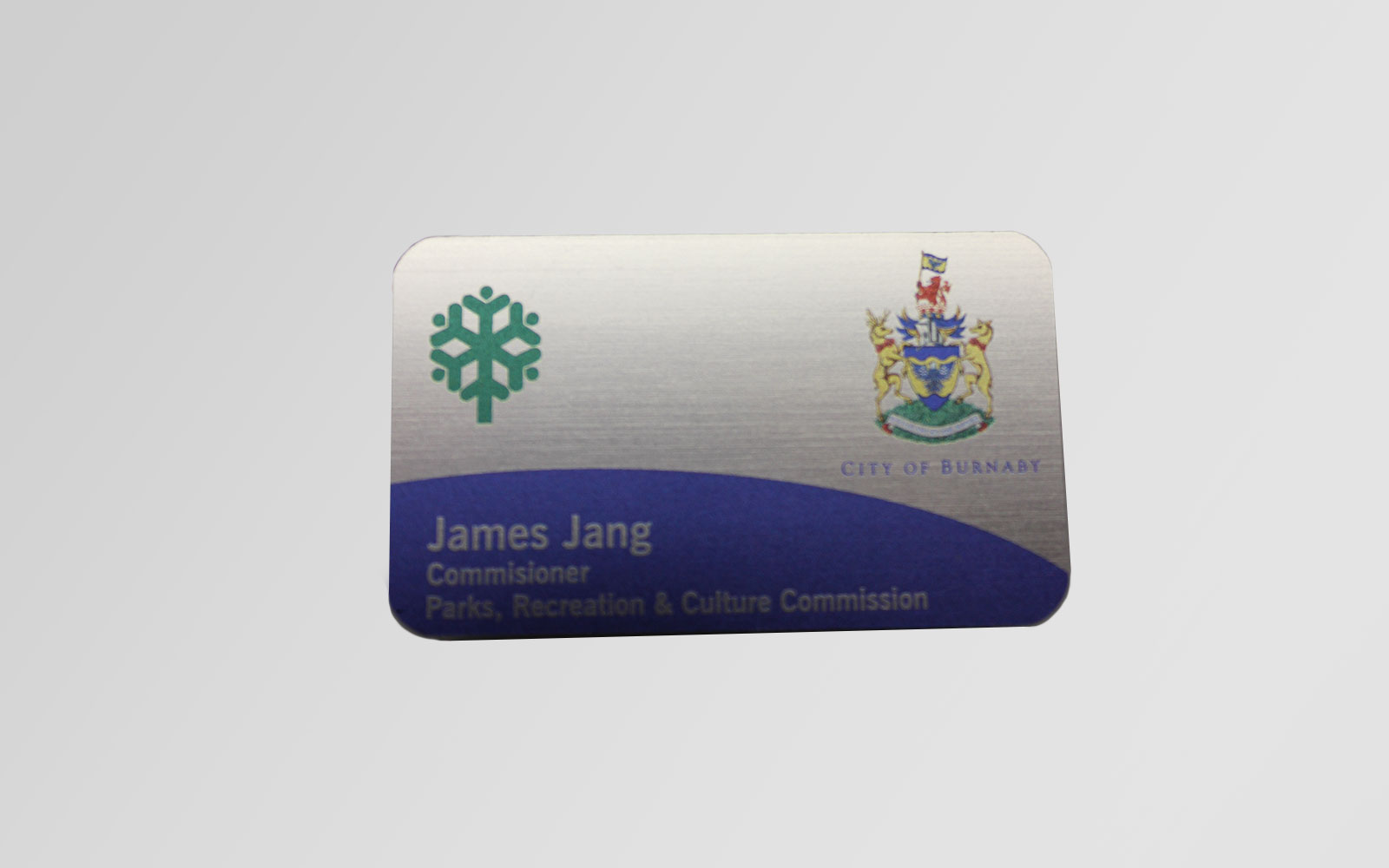

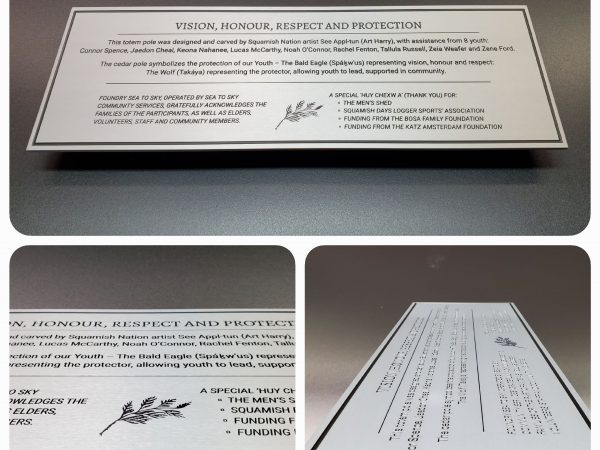

ADA Tactile and Braille Signage

Discover the importance of ADA tactile signs and braille signage for businesses. Our expertly crafted ADA and braille compliant signs ensure inclusivity and compliance. Explore our range today!

-

Laser Engraving and Laser Cutting

Explore the world of our state-of-the-art laser engraving and cutting solutions. Our advanced technology brings intricate designs to life. From ADA tactile signage to industrial lamacoid tags to industrial prototypes, discover the possibilities today.

-

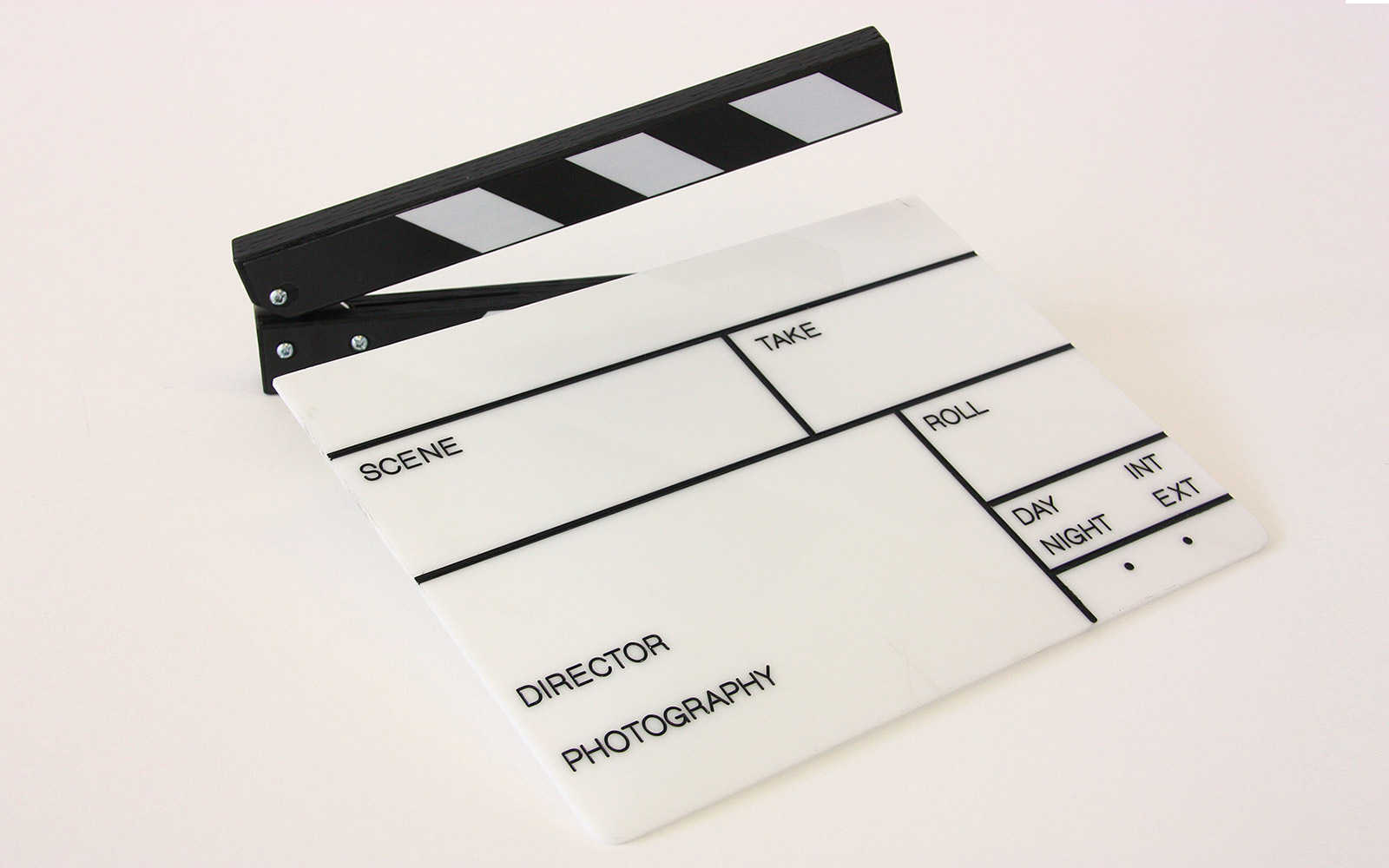

Movie Set and Props Signs

Movie sets require all kinds of signs and props. For years Permel custom sign company has honed its skills working with movie set producers to creatively produce signs and props economically that meet the exacting standards of the industry.

-

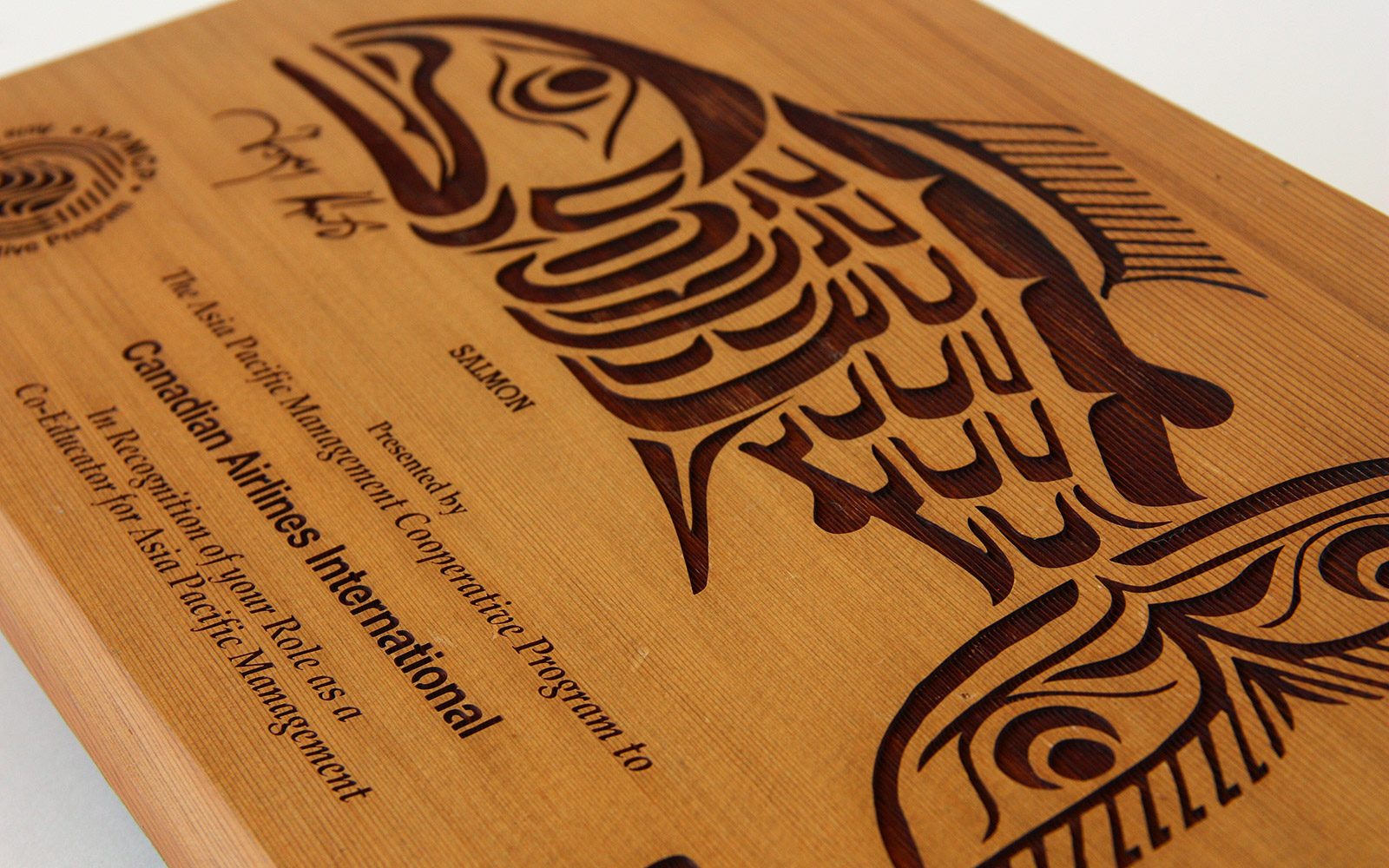

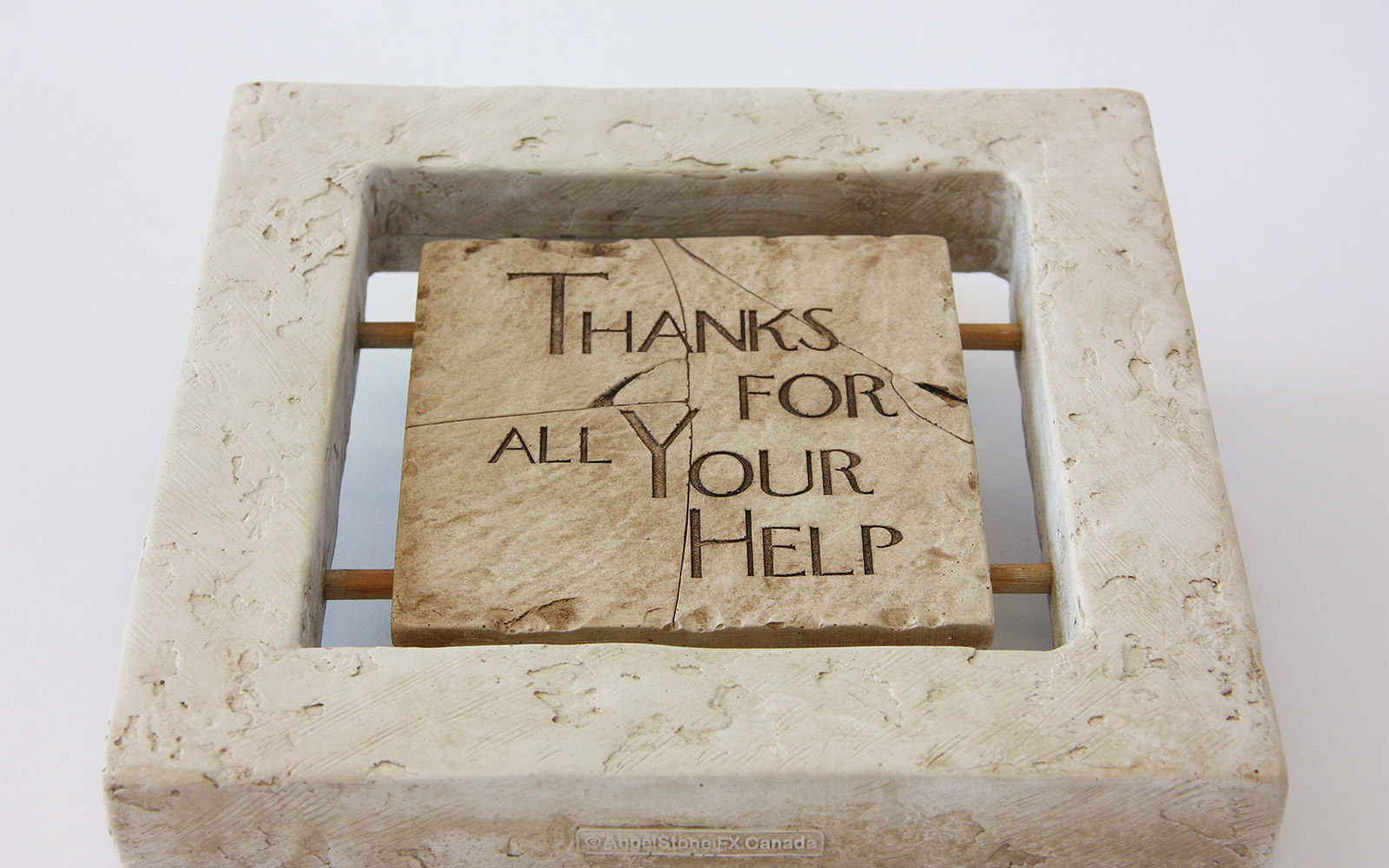

Commemorative Plaques

Discover the finest commemorative plaques for lasting memories and recognition. If you require a precision tooled or laser engraved commemorative plaque, our team at Permel can assist in creating a custom memorial plaque, dedication plaques, and more. Order now!

-

Reception and Showroom Signs

Elevate your business’s first impression with custom reception signs from . We offer professional design, quality materials, and fast installation services. Request a free quote today.

-

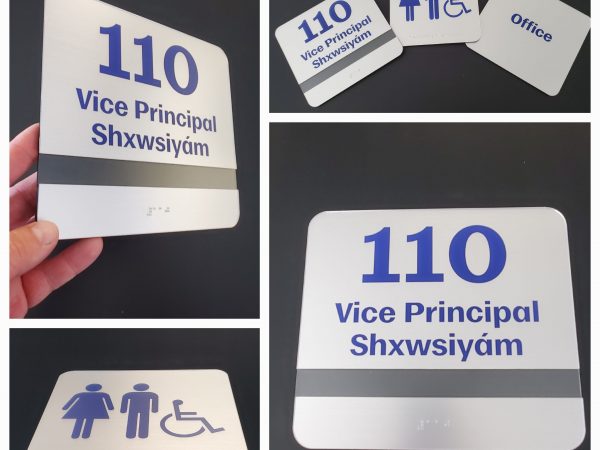

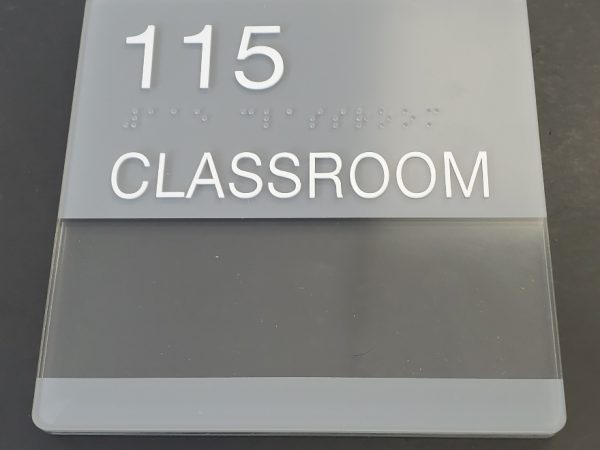

Schoolfit Classroom and School Signs

Elevate your school’s learning environments with custom SchoolFit Classroom Signage from Permel. Explore our range of high-quality, engaging, and informative signs designed to create a conducive atmosphere for education.

-

Yeti Laser Etched Tumblers

Elevate your hydration game with our laser-engraved drink tumblers. Discover premium quality, customizable designs perfect for both personal use and business identity gifts. Explore now!

Are you a Permel Trade Signage Partner? If you are not...

Get in Touch!